CNC Laser Cutting Machines: Revolutionizing Precision Cutting

CNC (Computer Numerical Control) laser cutting machines have transformed the landscape of precision cutting across various industries. These machines utilize laser technology controlled by computer programs to precisely cut through materials with unparalleled accuracy. Here’s a breakdown of their uses, parts, advantages, and how AYZ Trading Company is leveraging them to offer exceptional services:

CNC Laser Cutting Machines

So, What is CNC Laser Cutting Machines!

What is?

Laser cutting machines feature high-powered and highly accurate laser beams that are designed to produce precision cuts and clean etches on a wide gamut of materials. These machines are usually used to cut materials in industrial manufacturing applications such as structural and piping materials along with metal plates. The laser beams on laser cutting machines are responsible for burning, vaporization, or melting excess material, resulting in precision-quality cuts.

Used For?

Although “laser” is an abbreviation for a highly serious and intense term, it has a simple meaning: narrow and coherent light. So the laser must generate intense and focused light – and if enough light is concentrated into a single area, it can cut and burn things like a hot, sharp knife. The initial stage is to create light. However, not all light suits a laser beam; we require light beams that collaborate. We use monochromatic light, meaning all light beams have the same wavelength. For example, the laser beam may emit only blue light instead of your lamp’s white light, which contains numerous hues and has a broad spectrum.

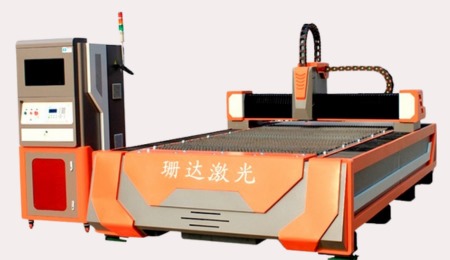

Fiber laser cutting machine

The optical fiber laser cutting machine developed and produced by our company is shown in Fig. 2, with a gantry structure.

The transmission part is driven by gear and rack.

The cross beam moves in the X-axis on the bed, and the slide seat moves in the Y-axis on the cross beam.

Uses of CNC Laser Cutting Machines

Industrial Manufacturing

CNC laser cutting machines are extensively used in industrial manufacturing processes for cutting materials like metal, plastic, wood, and composites with high precision.

Prototyping

They play a crucial role in prototyping by enabling rapid and precise fabrication of intricate designs, allowing companies to test their concepts before full-scale production.

Custom Fabrication

From signage and decorative elements to intricate parts for machinery, CNC laser cutting machines are employed in custom fabrication to produce unique and intricate designs.

Automotive and Aerospace

These machines are integral in the automotive and aerospace industries for cutting precise components from various materials used in vehicle and aircraft.

Our Working Process

Power Up / Test Cycle

High degree of transparency on the real equipment was purchased through a verification test that shows the machinery in action make an entire production cycle.

Set-a-Size

Configuring the machine size as a function of the product to be subjected to the transformation process through the execution of pre-tests.

Equipment regeneration

Regeneration process of each piece of equipment sold, improving performance and ensuring optimal operation.

Product lines Integration

Process of research and selection of the best machinery for the integration of a production line.

Specifications

| Specification | Country of origin and manufacturer | |

|---|---|---|

| Model | GC1530F Fiber laser cutting machine | GoodCut CNC |

| Warranty | 2 years | |

| Working Area X*Y | 1500*3000mm | |

| Laser type | Raycus/ MAX | |

| Laser power | 1500W | |

| Laser cutting head | Au3tech auto focus | |

| Control system | Au3tech | |

| Software | Au3tech | |

| Motor and driver | Leadshine servo motor driver | |

| Reducer | Shimpo reducer | Japan |

| Pneumatic component | Japan original SMC pneumatic | Japan SMC |

| Electrical | France Schneider electric switch | France Schneider |

| Machine frame | Heavy steel welded frame | |

| Industrial exhaust smoke system | Yes | |

| Max Velocity of Movement | 80m/min | |

| X/Y position accuracy | ±0.03mm/m | |

| X/Y Reposition Accuracy | ±0.01mm | |

| X/Y axis Max Acceleration | 1.0G | |

| Transmission | X Y: rack and pinion, HIWIN guide rails Z: TBI ball screw, HIWIN guide rails | Taiwan YYC rack and pinion Taiwan HIWIN guide rails Taiwan TBI ball screw |

| Voltage require | 380V 50/60HZ 60A | |

| Machine working temperature | 0℃-40℃ | |

| Other parts | S&A Water chiller Air Fan |

Parts of CNC Laser Cutting Machines

Laser Source

The laser source generates the high-energy beam used for cutting. It's typically a CO2 or fiber laser, depending on the material being cut.

Cutting Bed

This is the surface where the material being cut is placed. It often includes features like a grid or vacuum system to secure the material in place during cutting.

Lenses and Optics

These components focus and direct the laser beam onto the material with precision, ensuring accurate cutting.

Controller

The controller interprets the CNC program and coordinates the movement of the laser cutter to achieve the desired cuts.

Motion System

Consisting of motors and drive systems, the motion system moves the laser head according to the programmed instructions, allowing for intricate cuts.

Technical Parameter

Products Samples

CNC Laser Cutting Machines

Precision

CNC laser cutting machines deliver accuracy down to the micron, ensuring that your designs are faithfully replicated for betterment.

Quality

AYZ Trading Company use the latest technology and quality control measures to ensure that each cut meets the highest standards of excellence.

Versatility

From small-scale prototypes to large-scale production runs, we have the capabilities to handle projects of any size and complexity.

Reliability

With our commitment to efficiency and reliability, you can trust AYZ Trading Company to deliver your projects on time and within budget.

CNC Laser Cutting Machines Products

Do you need help? Talk to one of our consultants ...